New Items

Down ARC Reduced Threaded Studs

Product Description:

Down Arc Reduced Threaded Studs offered provides for superior fastening finish support as desired by the customers. These Down Arc Reduced Threaded Studs help in saving time, helps in avoiding the requirement of punching holes through the material on which fastening is been done as well as also help in providing for superior fastening finish that is durable as well as long lasting. Here, the reverse face of component can be covered/painted to ensure no presence of rear side marking.

Product Description:

Down Arc Reduced Threaded Studs offered provides for superior fastening finish support as desired by the customers. These Down Arc Reduced Threaded Studs help in saving time, helps in avoiding the requirement of punching holes through the material on which fastening is been done as well as also help in providing for superior fastening finish that is durable as well as long lasting. Here, the reverse face of component can be covered/painted to ensure no presence of rear side marking.

Features:

+ Designed to deliver consistent performance

+ Allows for better production flexibility

+ Helps in achieving leak proof fastening

+ Can be made available in a wide choice of metal options

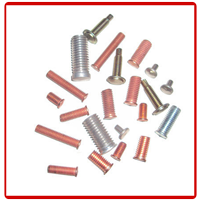

Capacitor Discharge Studs

Product Description:

We manufacture a wide range of Capacitor Discharge Studs that is available in various sizes and specifications. The diameter ranges from M3 to M8 with or without threads, or with interval thread tapped bush. These are manufactured using mild steel or stainless steel (304, 316); aluminum alloy AlMg3, or in special sizes (square / round), lead-free brass studs. Available in standard lengths from 8 to 40 mm in increments of 2 mm, M3x10, M3x12 and threads according to Metric/UNC or Imperial (BSW) dimensions.

Product Description:

We manufacture a wide range of Capacitor Discharge Studs that is available in various sizes and specifications. The diameter ranges from M3 to M8 with or without threads, or with interval thread tapped bush. These are manufactured using mild steel or stainless steel (304, 316); aluminum alloy AlMg3, or in special sizes (square / round), lead-free brass studs. Available in standard lengths from 8 to 40 mm in increments of 2 mm, M3x10, M3x12 and threads according to Metric/UNC or Imperial (BSW) dimensions.

Advantages:

+ Saves Time: A stud weld takes only a split-second to make and only two-three seconds to re-load the welding tool.

+ Saves Material: The component to which the fasteners are welded is not weakened by drilling - as a result plate thickness can be reduced. In addition, this process alleviates the need for punching holes and what's more - the reverse face of the component can be painted or covered as there is no rear side marking.

+ Saves Labor: Semi-skilled operators too can quickly learn to make perfect stud welds consistently

+ Increases Design and Production Flexibility: Access is only necessary from one side of the job - the equipment is readily portable and may even be bench-mounted. The designer has greater freedom and this production flexibility, with special auto-feeding studs, makes it possible to have methods of assembly that would otherwise be impractical.

+ Product Quality: Provides leak proof fastening. Leaves a smooth unbroken finish on the rear/reverse side of the component or fabrication

+ Wider choice of metals: Dis-similar metals can be welded as long as both are conductive, e.g. brass to steel, brass to copper, aluminum to die-cast zinc.

Application Areas:

+ Automobile body under frames

+ Cookware & kitchen appliances

+ Metal furniture

+ Stainless steel equipment

+ Insulation work (such as in air-conditioned rail coaches)

+ Control panel fabrication

Short Cycle Welding Studs

Product Description:

We provide a comprehensive range of Short Cycle Welding Studs that is manufactured using mild steel with or without plating finish or stainless steel 304, 316. It is available in the standard dimensions upto M8 in diameter. These conform to EN ISO 13918 standard and are used for short-cycle applications.

Product Description:

We provide a comprehensive range of Short Cycle Welding Studs that is manufactured using mild steel with or without plating finish or stainless steel 304, 316. It is available in the standard dimensions upto M8 in diameter. These conform to EN ISO 13918 standard and are used for short-cycle applications.

Cold Forged Items

Product Description:

Cold Forged Items offered by us are manufactured using high grade raw material which offers excellent strength. These are widely used in automotive industry, light engineering goods industry, aeronautical components and many more. We offer these in various technical specifications to meet the diverse requirements of our clients.

Product Description:

Cold Forged Items offered by us are manufactured using high grade raw material which offers excellent strength. These are widely used in automotive industry, light engineering goods industry, aeronautical components and many more. We offer these in various technical specifications to meet the diverse requirements of our clients.

Stud Welding Collets

Product Description:

Our range of Stud Welding Collets is manufactured using copper alloy collet that is used for CD Welding. These are available in various sizes such as M3, M4, M5, M6, M8, & M10 and in the length 40 mm upto 300 mm. Stud Welding Collets are used as consumables for Capacitor Discharge Stud Welding Systems and others.

Product Description:

Our range of Stud Welding Collets is manufactured using copper alloy collet that is used for CD Welding. These are available in various sizes such as M3, M4, M5, M6, M8, & M10 and in the length 40 mm upto 300 mm. Stud Welding Collets are used as consumables for Capacitor Discharge Stud Welding Systems and others.